Capitalizing on renewable energy

When you choose to make an investment in creating renewable energy from biowaste, you want to make sure you employ the right technology from the right partner. Whether your goal is to produce electricity, liquid fuels, hydrogen or RNG, it all starts with biogas. And DVO is the U.S. market leader for anaerobic digestion and environmental engineering for maximum biogas production. We have a track record of delivering proven solutions and services for more than 30 years.

Your Performance Demands Our Solution

Many happy returns

Many happy returns

You’ll realize a return on investment in renewable energy sooner and for a longer period when you step up to a DVO solution.

Only the best

Only the best

With DVO you’ll know you’ve done the best you can for investors, regulators, environmental groups, media and communities.

Not our first rodeo

Not our first rodeo

You’ll have an easier path to successfully finance and complete a project thanks to DVO’s track record and proven reliability.

Farmer preferred

Farmer preferred

A DVO digester gives you a significant differentiator when trying to bring on new dairies or other animal agriculture operations for biogas production.

Developer and Investor Benefits

- More Biogas – Our biogas production per pound of volatile solids far exceeds the industry average. More biogas = more revenue.

- Easy to operate and maintain – Designed to be operated by the site owner or farmer, DVO digesters are simple to maintain and optimized for reliability. Most installations still operate today, including the first in 2001.

- Carbon footprint – For given feedstocks, no other digester design comes close to DVO for its renewable energy output and greenhouse gas emissions reductions.

- Saleable byproducts – Recycled biosolids are a high-quality bedding for cows or can be used as a soil amendment. A liquid product is an effective fertilizer for crops.

- Unparalled performance – A DVO anaerobic digester system greatly reduces odors, is cost-effective, scalable, operates automatically and requires low maintenance.

- Multiple feedstocks – DVO’s anaerobic digester can process a tremendous variety of organic waste streams.

Renewable Energy in Many Forms

Because a DVO anaerobic digester delivers the most biogas per ton of organic waste, it also creates the most renewable energy. Biogas from the digester can be used to create:

- Renewable Natural Gas (RNG) is produced from upgraded biogas and piped out of the facility into the energy grid

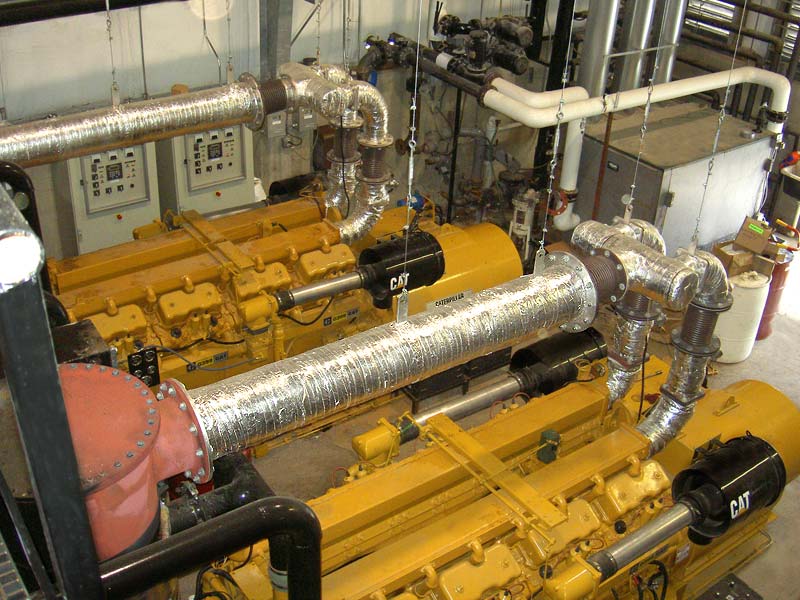

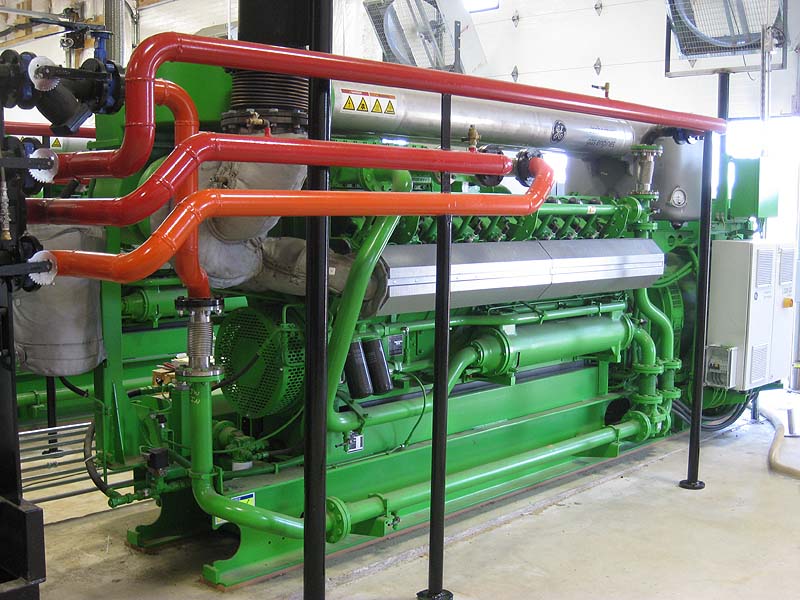

- Electricity from on-site generators fueled by biogas can be used or sold into the grid

- Liquid fuels such as dimethyl ether (DME), biodiesel, jet fuel

- Hydrogen for fuel cells or other energy applications

Making a Digester Pay

The value of renewable energy continues to grow, and societies reward biogas producers with incentives when they meet certain requirements. Federal and state laws are unlocking economic opportunities for producers to sell renewable natural gas for a profitable return.

Here are a few more prominent incentive programs:

RINs. Credits created as part of the Renewable Fuel Standard, a program to reduce greenhouse gas emissions and expand use of renewable fuels in the U.S. The most attractive RINs to the biogas industry are D3 and D5 RINs because of the EPA-registered “pathways” available for biogas producers to generate D3 and D5 renewable fuels. Pathways are technological processes that meet EPA standards for carbon reduction.

LCFS. The Low Carbon Fuel Standard is a market-based program that focuses specifically on reducing carbon intensity (CI) of fuels used within California. It was created by the California Air Resources Board (CARB). Credits are generated as fuel is consumed within transportation, specifically when the fuel has a CI score lower than the target established by CARB.

eRINs/eLCFS. Credits produced when qualifying biogas is used to generate renewable electricity for the charging of electric vehicles.

Renewable Energy Certificates (RECs). Many states have some form of a renewable energy portfolio standard, and many electric utilities buy RECs for compliance. RECs are tradable, non-tangible energy commodities representing proof that 1 MWh of electricity was generated from a qualified renewable energy resource.

Carbon Offset Credits. In some U.S. markets, carbon offset credits may be earned by reducing GHG emissions, such as methane recovered from an anaerobic digester biogas system. These credits have an economic value and can be bought and sold on commodity exchanges, through private transactions, or through credit aggregators.

Helpful Links:

- EPA Anaerobic Digester Project Planning and Financing

- The American Biogas Council has developed a RIN Calculator

Fertilizer Byproducts Add Value

Phosphorous and nitrogen are valuable crop fertilizers, and the DVO digester captures these nutrients as byproducts of the digestion process. The finished by products have commercial value and can be sold to crop farmers. Unlike raw manure, treated liquid from the anaerobic digester is made “plant-ready.” It can be irrigated to a growing crop, making nutrient management more flexible. An optional secondary “fine-solids separation” step allows for the majority of a farm’s phosphorus to be placed into a cake form. It can then be transported to fields that need it while also allowing the liquid volume to be pumped through a pivot irrigation system.

Digester Type Performance Comparison

| Two-Stage Linear Vortex™ | Complete Mix | Covered Lagoon | |

|---|---|---|---|

More biogas means more D3-RIN revenues per cow | 115 | 80 | 50 |

Design generation | 3rd | 2nd | 1st |

Plant longevity (avg years) | 30+ | 15-30 | 5-10 |

Lowest cost per MMBtus output/time | Best | Poor | Poor |

Preferred by farmers | Best | Poor | Poor |

Can process 100% of food/organic waste | Best | Okay | Poor |

Performance is not “seasonal” | Best | Best | Poor |

Ability to divert all VS from lagoon storage | Best | Poor | Poor |

Processes more dairy waste than any other | Best | Poor | Poor |

Flush, scrape and vac-collection dairies served | Best | Okay | Best |

Superior animal bedding quality | Best | Poor | Poor |

No composting of solids needed | Best | Poor | Poor |

Pathogen destruction (e-coli, salmonella, etc.) | Best | Okay | Poor |

Odor and weed-seed destruction | Best | Okay | Poor |

Methane emissions avoided per cow | Best | Okay | Poor |

Greenhouse Gas (GHG) impacts avoided | Best | Okay | Poor |

Renewable power generated per ton of waste | Best | Okay | Poor |

Positive carbon footprint | Best | Okay | Poor |

Digester is certified “Newtrient Recognized” | Best | Poor | Poor |

Efficient, optional ammonia recovery step | Best | Poor | Poor |

Suitable for co-generation (e.g., food waste and manure) | Best | Okay | Poor |

| Download PDF |

Why DVO? It’s simple. Their system digests ALL the waste from a dairy. Nothing bypasses. The manure is thoroughly and efficiently processed, and the gas output is steady and predictable year-round. Together this means significantly more biogas ‘per cow’ is produced than with other digester designs. DVO also has an excellent track record of success. These things are good for the environment and the local community...and tend to make our investors happy too. It also helps that dairy farmers already know DVO, and they like the other benefits the DVO system offers them.

– Grant Zimmerman CEO, Amp Americas – owner of North America's two largest biogas-to-CNG sitesRelated Projects

Goshen, WI

Urban organics & dairy waste, 3.3MW

Fair Oaks Dairies, IN

12,000 milking, CNG + 1MW

Herrema Dairy, IN

3,750 milking, 800kW

Dongying, China

5,000 milking equiv. CNG output

Pixley Biogas, CA

2,500 Milking, 750kW by Regenis Corp.

Fresh Dairy One, Australia

10,000 total cattle, 3MW

Biotown Ag, IN

Urban Organics/Hog/"Mixed" digester 6.3MW (6x 1.05MW)

Fair Oaks Dairy

Fair Oaks Dairy uses DVO's anaerobic digester to convert waste from 11k cows into biogas, reducing emissions by 94%, cutting odors by 97%, and saving 1.5M gallons of diesel yearly.

Go to project

Green Mountain Dairy

At Green Mountain Dairy, the Rowell brothers use DVO's digester to turn manure & ice cream waste into power, generating 2M kilowatts annually, serving 4k homes, & making farming greener in Vermont.

Go to projectAdditional Resources

Related Frequently Asked Questions

How do I get started?

With only a few basic pieces of information, namely:

- What is being processed (data such as TS, TSS, pH are helpful too)

- Daily volumes (max)

- Timeframe (when desired)

We can estimate both the capital and operating costs. Melissa VanOrnum, 920-418-4543, will be glad to help you investigate at no obligation.

Who can I contact for more information?

Contact Melissa VanOrnum, DVO Vice President Marketing, at 920-849-9797 or info@DVOinc.com

What will my utility pay for the electricity?

This will differ greatly from state to state, and region to region.

Is it possible to store biogas and generate power during peak hours only?

Yes it is — when it is economically practical to do so. But that is not typical. To take advantage of a higher peak rate one must install 2-3x the power generation equipment (to burn the gas created during off-peak hours in a shortened timeframe) — which engines will also then be cycled on/off and idled daily. Cycling engines is hard on them and as a result their maintenance costs also increase. In short: When the financial return of biogas storage more than covers significant additional capital and operating expenses, DVO can provide this capability.

Can I use the electrical power that I generate?

Yes. You can use it and sell what you do not use to the power company. However, in the majority of cases it has been advantageous to sell all of it to your utility and buy what you need off the grid.

What does it cost to install?

The installation cost is relative to the volume of waste to be processed daily. The particular characteristics of any waste stream can also influence system design and cost as well. Some upfront testing is usually desired.

Do I need a DVO digester? Or will any digester do?

As digester designs differ, so can their performance. Partly because a DVO digester's unique design offers a "guaranteed retention time," waste streams are more thoroughly processed than with other AD designs. The benefit is both a higher level of Phos removal and more economical operation.

DVO is initially rolling Phosphorus Recovery out to its customers, but may also offer this process to other AD owners at a later date (TBD).

How do I know yours is a good design when everyone else claims theirs is “the best available?”

- Don't take our word for it. The U.S. EPA keeps track of U.S. farm digester installations: https://www.epa.gov/agstar/livestock-anaerobic-digester-database Download this Excel spreadsheet, sort it by the "System Designer" column, and you will see how many DVO has sold in the previous few years (versus competing systems). You will also see repeat DVO customers – a key indicator of customer satisfaction.

- Talk directly to our customers. Any of them. Unlike others we don't provide a "referral sheet." Our customers are our best salespeople, and we encourage you to ask them about their experience with our system. For example, in the dairy industry some of the largest and most respected names (such as Fair Oaks, Bos, and Bettencourt) and operations of all sizes and configurations (scrape, flush, vac, sand etc.), employ our system.

- Compare actual performance figures. It's hard to find complete and accurate performance figures from other companies, especially for manure waste streams that do not contain any substrates (conveniently making valid apple-to-apple comparisons impossible). The EPA commissioned an extensive study at one of our sites, our first built – and the results are available here.

Is your “Guaranteed Retention Time” one reason why DVO digesters produce more biogas using the same feedstocks than other designs?

Yes. It’s also why we see better odor reduction and pathogen control.

As my operation expands, can my digester expand with it?

Yes. There are two ways to expand your digester. One is to lengthen the digester like you might lengthen a barn. The other option is to build a second digester next to the first and have the two share a common wall.

How much does it cost?

The cost will vary considerably depending on the size and layout of the operation. We can provide a rough estimate after gaining an understanding of certain aspects of your operation. We work hard to keep our system costs down without impacting system performance or reliability.

What are your digester’s products/revenue streams?

Biogas, which can be used to create electricity or in a boiler to create steam. Or it can be scrubbed to create natural gas. Other revenue streams include a solid, a liquid and waste heat.

- Digested solids can be used as a high-quality animal bedding, replacing other bedding sources such as sand or sawdust. Solids can also be sold as a peat-moss replacement or a fertilizer.

- The digested liquid effluent can be applied to a growing crop, reducing the likelihood of runoff and increasing crop yield.

- Other revenue streams include the possible sale of carbon credits, renewable energy credits, and the Federal Production Tax Credit.

- Waste heat in the form of hot water is a byproduct that digester owners are using to heat various parts of their operation (parlor, maintenance shop, etc.)

Latest News

‘We have a tremendous story to tell’: Dairy farmers praise on-farm digesters

A panel of experienced dairy farmers share insights about the opportunities that come with operating on-farm digesters at Biogas Americas 2024.

Read MoreBiogas Americas 2024: DVO’s Melissa VanOrnum and the importance of farmers’ voices

On-farm biogas 'a huge and exciting opportunity' for farmers and developers

Read MoreDVO welcomes calls to cut New York methane emissions with anaerobic digestion

Building more anaerobic digesters in New York could cut methane from dairy manure by 56.5%

Read More